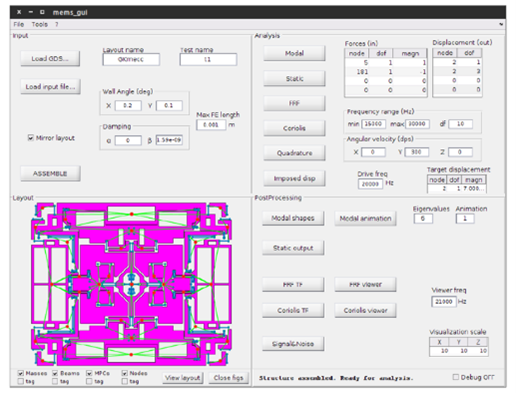

The design of MEMS devices usually involves several Finite Element (FE) analyses, each with different parameters (e.g. beam thicknesses) to tune the characteristics of the sensor. This trial-and-error procedure is tedious and time-consuming, even more so considering that typical FE models may count 100k-1M degrees of freedom. For this reason, our group developed a Matlab code, feMEMS (see the old GUI on the left), to model gyroscopes with beam elements and lumped masses, which has been successfully used for parametric optimization (average iteration time: 0.5s).

In this thesis, the candidate will have to reorganize feMEMS using an object-oriented framework to develop new features, possibly integrating and/or making it compatible with other tools used inside our group (e.g. yaFEc). Possible extensions include the implementation of von Karman beams, (special) shell elements, and sub-structuring techniques (depending on the candidate’s commitment). Code and features will be tested on a real MEMS layout to be optimized.